Mobiles and the environment - can we be greener?

Many of our readers no doubt intend to buy new mobiles, laptops and other gadgets this Christmas for friends and relatives – how about a new smartphone or tablet to while away the cold nights?

Keeping up to date with the latest tech has become an obsession for many people, but very people give any thought to how these devices are made and what happens to the old ones. Even the manufacturers themselves are often guilty of failing to ensure that last year’s technology is disposed of in environmentally sound ways.

Environmental hazards

By 2016 it’s expected that electronic waste will account for more than 90 million tons, with most of that simply being dumped in landfills. Green initiatives are still few and far between but some companies have made concerted efforts in recent years to tackle the problem. Apple for example appears to take pride in its many environmental responsibilities with investments in huge renewable energy plants, simpler packaging and a move designing products that are more power-efficient and less wasteful. Apple has also improved its transparency about its supplier responsibility code and other initiatives.

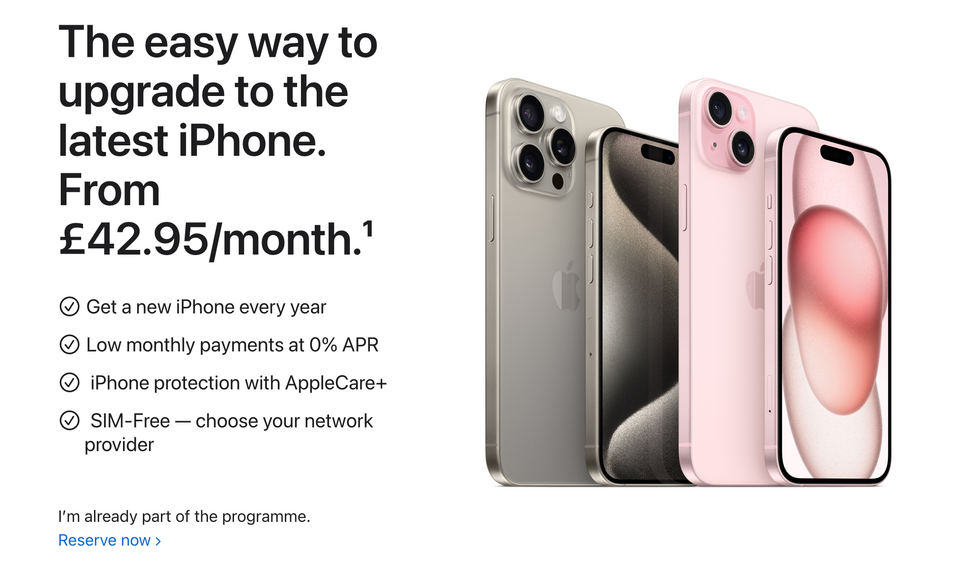

Today, the ultra slim form factors of modern gadgets are incredibly hard to disassemble and recycle, but this wasn’t always the case. More traditional tower-style computers are simpler to upgrade and change parts – fancy a new motherboard or RAM upgrade? Just swap out the old bits for new ones. But modern computers and smartphones have few user-replaceable components, and mobiles in particular are upgraded to the latest models with with alarming frequency. There’s a new iPhone? Better chuck out the old one!

As the penetration of mobiles has increased exponentially around the world, we’ve all become used to buying a new device and throwing away the old one. Few devices can be recycled easily, and they contain dozens of harmful metals and chemicals such as mercury, arsenic and beryllium, to name just a few. Once the devices are disposed of, these chemicals often end up polluting the groundwater in poor countries and harming local communities. This makes recycling them through official channels of paramount importance – Samsung, Apple and other manufacturers do at least have schemes to trade-in and recycle.

As an example of the environmental impact these devices can have, many of today’s mobiles contain tin from Bangka island in Indonesia, which according to the Friends of the Earth is wiping out the coral and killing the tropical forests. Companies such as Philips and Motorola have all publicly admitted they source, or have done in the past, tin from the island. Tin is mainly used a solder for phones and other gadgets, with a third of the world’s mined tin coming from Bangka.

Just how are gadgets recycled?

The recycling process can be extremely complicated and fraught with difficulties in actually extracting the usable materials. When you submit a phone for recycling, it’s initially assessed for damage (dents, scratches and the like) and if it’s free of defects it will be reset and wiped, then repackaged and resold, often in another country.

Unfortunately, the whole process is very difficult to mechanise – most of the assessment and testing is still carried out by hand, which adds to the cost of recycling. If the gadget can’t be resold it’s normally taken apart and shredded to retrieve the metals – steel, copper, aluminium can all be recycled, as can glass screens. In this cases, very few components of the original product end up in landfill, but it all depends on how valuable the raw materials in the device are and how difficult extraction is. If it costs more than the effort to recycle, it will more than likely be dumped.

The difficulties of recycling smartphones

According to iFixit’s Kyle Wiens, “The big problem the electronics industry is facing as a whole is products are getting lighter and lighter. This is great for consumers but a nightmare for recyclers”. Obviously smaller, lighter and more complex devices are much more difficult to dismantle.

Furthermore, it might surprise you to know that glue is used extensively in products such as the iPhone and iPad – adhesives ensure that batteries stay in place, and thermal paste is often applied to CPUs to help them keep cool. All of this is hard to remove prior to recycling. Batteries themselves are a challenge because of the dangers of an explosion and risk of fire if not handled properly.

Most components which are glued need to be prized free by heating – screens for example need suction cups to be removed without damage. Other items make the process challenging too – special types of bespoke screws, dangerous metals, glass and plastics present difficulties that all require special techniques and tools to remove safely.

Recyclable by design

Companies such as iFixit find that Apple’s products in particular score low on the repairability and recyclability scores. But Apple is known to be actively engaged with recycling companies to figure out the best way to recycle their products, and also in the development of suitable recycling tools.

As more devices are sold every year, making them highly recyclable should be a priority for the manufacturers. Steps that could be taken include using standard screws and minimising the use of adhesives, as well as making products easier to dismantle in general. That also includes more user-serviceable components such as swapping out the RAM on a laptop (RAM is often soldered to the motherboard on modern machines, which means that when it starts to become sluggish you’re more likely to simply upgrade to a new one).

Perhaps these improvements would mean design compromises were unavoidable, and therefore the products would inevitably be less attractive to consumers. But some companies such as Dell are making great strides to make products cheap and easy to recycle, through the use of organic plastics and a prominent global recycling programme.

5 steps to greener devices

There are steps that could be taken to reduce the impact of our electronics on the environment. Here’s five to start:

- Switch to energy saving batteries such as the Organic Radical Battery (ORB) which doesn’t use heavy metals and can charge very quickly

- Operators should change the length of our contracts – rather than 18 months (after which we are tempted to upgrade), offer longer contracts and options to lease

- Design products with disassembly, repair and recycling in mind – no glue or special screws to prevent users from opening them

- Use greener materials (or fewer materials), such as plastics made from corn starch, which is biodegradable

- Reduce unnecessary packaging and accessories – there’s no need to provide a charger with a smartphone as most users already have several that can be reused

It’s up to us…

Certainly, companies such as FairPhone are already designing attractive and powerful devices while also considering their environmental and ethical impact.

In the end, the choice of how often we upgrade and which devices we buy is up to us. But we can also pressure the electronics manufacturers to provide greater transparency about their green credentials, and of course encourage them to do more.

So when you’re happily playing with your new mobile this Christmas, spend a moment to consider where all the toxic chemicals and metals it contains will end up in a year or two.